Industrial Automation

Industrial Automation Solutions: High-Performance, Durability, and Robust Control for Industry Applications

In the fast-paced world of industrial automation, performance, reliability, and efficiency are critical. MACRO NEO specializes in providing cutting-edge solutions designed to meet the rigorous demands of industrial environments. Whether for process control, robotics, machine vision, or smart factory systems, our industrial automation solutions are engineered for high performance, long lifespan, and exceptional resistance to interference, ensuring optimal operation in the most challenging conditions.

As industries increasingly adopt smart manufacturing and Industry 4.0 technologies, the need for robust and scalable automation systems continues to grow. MACRO NEO is committed to helping our clients navigate this transformation by providing solutions that optimize productivity, reduce downtime, and ensure seamless control over complex industrial systems.

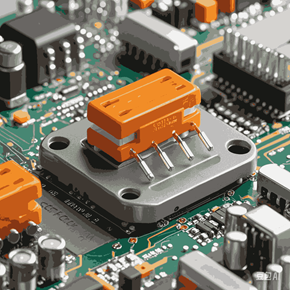

1. High-Performance Control Systems

Industrial automation systems require real-time control with high precision and reliability. At MACRO NEO, we offer advanced control systems that enable precise monitoring and manipulation of industrial processes, from assembly lines to energy management systems.

- Programmable Logic Controllers (PLCs): Our PLCs are designed for high-performance automation tasks in harsh industrial environments. Equipped with real-time processing capabilities, they offer fast response times and seamless integration with sensors, actuators, and human-machine interfaces (HMIs). Our PLCs are highly configurable, ensuring compatibility with diverse industrial processes.

- Industrial PC Solutions: For more complex automation tasks, our industrial PCs offer advanced computing power in a rugged form factor. These systems are equipped with robust hardware to handle heavy computing loads and are highly adaptable for use in everything from data acquisition to process control.

- SCADA Systems: Our Supervisory Control and Data Acquisition (SCADA) solutions provide centralized monitoring and control over industrial processes. They offer real-time data acquisition, alarm monitoring, and reporting capabilities that help operators optimize system performance and ensure process efficiency.

With MACRO NEO’s control systems, industries can automate complex tasks with precision, reducing human intervention, improving operational efficiency, and enhancing overall productivity.

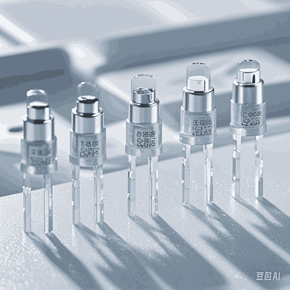

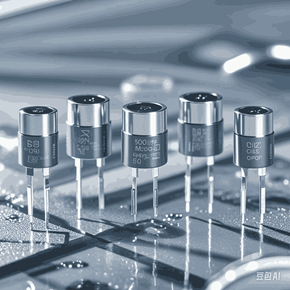

2. Durability and Longevity in Harsh Environments

Industrial environments are often characterized by extreme temperatures, high humidity, vibration, and dust, which can take a toll on electronic equipment. MACRO NEO designs automation solutions with durability and longevity in mind, ensuring that our products continue to perform reliably over time, even in the harshest industrial settings.

- Rugged Industrial Components: Our industrial automation solutions are built with rugged materials and sealed enclosures, ensuring that they remain operational in challenging conditions. Whether exposed to extreme heat, cold, moisture, or corrosive elements, our systems are designed to withstand these harsh environments.

- Extended Lifecycle: With a focus on high reliability and long service life, our solutions are engineered to operate with minimal maintenance, reducing downtime and repair costs. Our products undergo rigorous stress testing to ensure they meet industrial standards for MTBF (Mean Time Between Failures) and MTTR (Mean Time to Repair).

- Thermal Management: Effective thermal management is essential for ensuring the longevity of industrial systems. We offer solutions with integrated heat dissipation technologies, including advanced cooling systems and heat sinks, to prevent overheating and extend the lifespan of critical components.

By focusing on durability and long operational lifespans, MACRO NEO helps businesses reduce operational interruptions and minimize maintenance costs in demanding industrial environments.

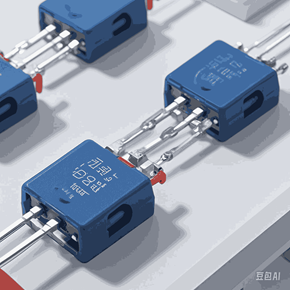

3. Antifactorial & Interference Resistance

Industrial automation systems often operate in environments with significant electrical noise, electromagnetic interference (EMI), and other disruptive factors. MACRO NEO’s automation solutions are built with advanced shielding and interference-resistant technology to ensure stable and accurate operation, even in such challenging conditions.

- Electromagnetic Compatibility (EMC): Our products comply with EMC standards, ensuring that they remain unaffected by external electrical interference and do not emit disruptive electromagnetic signals that could affect nearby systems. This is essential for ensuring the integrity and accuracy of control systems, sensors, and communications.

- Signal Integrity: For applications that require high-precision signal transmission, such as machine vision or robotic systems, our solutions incorporate advanced signal filtering and noise suppression technologies, ensuring that signal clarity is maintained even in the presence of electrical disturbances.

- Industrial I/O Isolation: We use optical isolation and galvanic isolation in our I/O modules to protect sensitive control systems from voltage spikes, surges, and other electrical anomalies, safeguarding the integrity of data transfer between devices.

By incorporating anti-interference technologies into our systems, MACRO NEO ensures reliable communication and control in environments subject to electrical noise and other disruptive factors, making our products ideal for use in industries like automotive, manufacturing, and energy.

4. Real-Time Monitoring and Predictive Maintenance

Industrial automation is increasingly linked to the Internet of Things (IoT) and predictive maintenance, which leverage data to improve system performance and predict failures before they occur. MACRO NEO integrates real-time monitoring and predictive analytics capabilities into our automation systems, helping industries stay ahead of potential issues and avoid costly downtime.

- IoT-Enabled Sensors and Devices: We offer a range of IoT sensors and devices that can monitor parameters such as temperature, vibration, pressure, and flow rate. These sensors transmit real-time data to central control systems, enabling operators to monitor performance and detect anomalies before they lead to failure.

- Condition Monitoring Solutions: Our condition monitoring solutions provide continuous health assessments of critical industrial equipment. By analyzing data from sensors, our systems can predict when maintenance is needed, reducing the likelihood of unexpected breakdowns and extending the life of equipment.

- Data Analytics and AI for Predictive Maintenance: Leveraging AI algorithms and machine learning, we analyze historical and real-time data to predict the failure patterns of machinery and components. This allows for predictive maintenance, enabling timely interventions and reducing the need for reactive repairs.

MACRO NEO’s monitoring solutions empower industries to adopt proactive maintenance strategies, reduce unplanned downtimes, and improve overall system reliability and efficiency.

5. Scalable and Flexible Automation Systems

In a rapidly changing industrial landscape, the ability to scale and adapt your automation systems is essential. MACRO NEO provides flexible and scalable solutions that can grow with your business needs, ensuring that your systems evolve as your production processes become more complex and interconnected.

- Modular Control Systems: Our automation systems feature a modular design, allowing you to easily add or remove components as needed. This makes it simple to expand or reconfigure your systems to meet new demands or integrate new technologies.

- Edge Computing for Industrial Automation: With the rise of Industry 4.0, edge computing is becoming increasingly important for real-time data processing and decision-making. Our solutions include edge computing modules that process data locally, reducing latency and improving system responsiveness in large-scale, distributed environments.

- Cloud Integration: To facilitate seamless connectivity, our automation solutions support integration with cloud-based platforms. This enables real-time remote monitoring, control, and optimization of systems across multiple locations, providing increased visibility and operational flexibility.

MACRO NEO’s scalable and flexible solutions provide industries with the agility they need to stay competitive in a rapidly evolving market, adapting to new technologies and operational requirements.

Why Choose MACRO NEO for Industrial Automation?

- High-Performance Systems: Our products deliver precise control and optimal efficiency in demanding industrial applications, from robotics to process automation.

- Durability and Longevity: Designed to withstand extreme conditions, our solutions offer long service life and reliability, reducing operational disruptions and maintenance costs.

- Interference Resistance: With advanced anti-interference technologies, we ensure stable performance even in environments with electrical noise or harsh physical conditions.

- Predictive Maintenance and IoT Integration: Our smart solutions provide real-time data and predictive analytics, helping you stay ahead of potential system failures and optimize maintenance schedules.

- Scalability and Flexibility: Our automation systems are modular, expandable, and adaptable to meet the evolving needs of your operations.

Get in Touch with MACRO NEO

At MACRO NEO, we are committed to providing advanced industrial automation solutions that drive efficiency, reliability, and scalability. Whether you're optimizing your manufacturing lines, implementing smart factory technologies, or improving process control systems, our solutions are built to meet your specific requirements. Contact us today to learn how our automation solutions can enhance your operational capabilities and support the future of industrial manufacturing.