Manufacturing & Quality Control

Manufacturing & Quality Control: Ensuring Excellence from Production to Delivery

At MACRO NEO, we understand that the success of a product relies not only on innovative design and development but also on the efficiency and quality of its manufacturing process. Our comprehensive approach to manufacturing and quality control ensures that every product is produced with the highest standards of quality, precision, and reliability. From supply chain management to production monitoring and rigorous quality inspections, we are committed to delivering products that meet your expectations and industry standards.

1. Supply Chain Management: Streamlined and Efficient

Effective supply chain management is critical to ensuring timely and cost-effective production. At MACRO NEO, we leverage our global network of trusted suppliers and partners to source the best materials and components for your product. Our experienced supply chain team works to minimize risks, reduce delays, and optimize costs, ensuring that every stage of the manufacturing process runs smoothly.

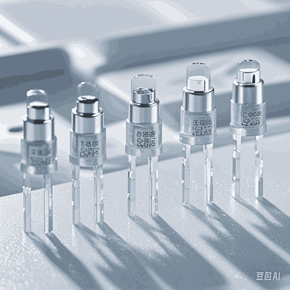

- Vendor Selection & Partnership: We carefully select and build long-term relationships with suppliers who meet our stringent standards for quality and reliability. This ensures that we can source high-quality raw materials and components for your product, whether it’s electronics, plastics, metals, or other specialized materials.

- Inventory Management: We maintain strict control over inventory levels, using real-time tracking and forecasting to ensure we have the right materials available when needed. This helps prevent production delays and minimizes stockouts.

- Logistics & Timely Delivery: Our logistics team coordinates the transportation and delivery of raw materials to the production facility, ensuring that everything arrives on time and in optimal condition. We manage both local and international logistics, navigating customs and shipping regulations to guarantee smooth deliveries.

- Cost Optimization: We continuously evaluate and negotiate with suppliers to ensure competitive pricing, without compromising quality. By optimizing the supply chain, we help keep your production costs low, contributing to a more profitable product.

This efficient supply chain management ensures that your product is made with the best materials, on time, and at the right cost.

2. Production Monitoring: Consistency and Efficiency

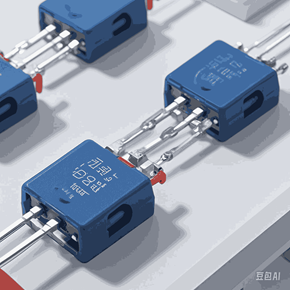

Once the materials are in place, MACRO NEO ensures that every step of the production process is monitored and optimized for efficiency and consistency. We employ advanced technologies and best practices to maintain high levels of productivity and quality control throughout production.

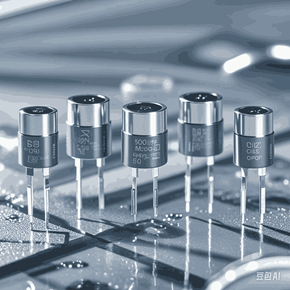

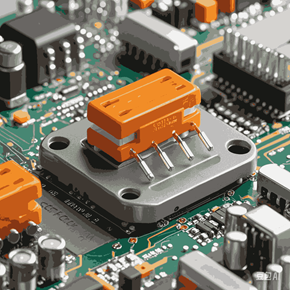

- Advanced Manufacturing Technologies: We use state-of-the-art manufacturing equipment and automated production lines to ensure precision and efficiency. Our facilities are equipped with robotics, CNC machines, and other automated tools to improve production speed while maintaining quality standards.

- Production Planning & Scheduling: We use lean manufacturing techniques to streamline production processes, reduce waste, and maximize throughput. Our detailed production scheduling ensures that the right resources are allocated to meet deadlines and maintain production efficiency.

- Real-time Monitoring: We implement real-time production tracking systems, which provide live updates on production status, material usage, and potential bottlenecks. This allows us to make immediate adjustments if necessary, preventing delays and ensuring that each step adheres to our quality benchmarks.

- Capacity Management: We ensure that we can scale production as needed to meet demand fluctuations. Whether producing small batches or large volumes, our flexible production lines can handle varying order sizes without compromising quality or timelines.

By combining advanced technology, efficient processes, and real-time data, MACRO NEO ensures that your products are consistently produced on time and to the highest standards.

3. Rigorous Quality Control: Uncompromising Standards

Quality is at the heart of everything we do at MACRO NEO. Our quality control (QC) system ensures that every product meets the strictest industry standards, from materials selection through to the final assembly. We take a proactive approach to quality management, with continuous testing, inspections, and improvements throughout the manufacturing process.

- In-Process Quality Control: We implement quality checks at every stage of production to catch defects early. This includes inspections during assembly, testing of electrical components, and evaluating the fit and finish of each unit. By performing quality checks at various points in the process, we reduce the risk of defects reaching the final stages of production.

- Automated Testing & Inspections: We use automated testing equipment to evaluate key product parameters such as performance, functionality, safety, and compliance with regulatory standards. This ensures consistent testing results and minimizes human error.

- End-of-Line Inspection: Before the products leave the factory, each unit undergoes a final inspection to verify that it meets all functional and aesthetic criteria. Our inspectors check for any visible defects, test electrical functionality, and ensure that the product is in perfect condition.

- Compliance & Certifications: We ensure that your products meet all required industry standards and regulatory certifications such as CE, FCC, RoHS, and ISO 9001. This helps ensure the products' market acceptance and compliance with international regulations.

- Continuous Improvement: We view quality control as an ongoing process. Our team consistently analyzes production data to identify trends, bottlenecks, and areas for improvement. By regularly reviewing our quality control systems and feedback, we implement improvements to enhance product quality and manufacturing efficiency.

Through rigorous quality control procedures, MACRO NEO ensures that every product leaving our facility is built to the highest standards, both in terms of functionality and durability.

4. Final Packaging and Delivery: Ensuring Safe and Timely Delivery

Once production and quality control are complete, MACRO NEO carefully packages the final products for safe transport and timely delivery. We take extra care in packaging to prevent damage during transit and to ensure that the products reach their destination in perfect condition.

- Packaging Design & Protection: We design packaging that not only protects the product but also enhances the customer experience. From customized boxes to protective inserts, we ensure that your products are well-packaged to prevent any damage during shipping.

- Global Shipping & Distribution: Our logistics team manages the distribution process, ensuring that your products are shipped globally to meet deadlines. We handle all aspects of shipping, including customs clearance and international regulations, ensuring a smooth delivery process.

- Tracking & Monitoring: We provide real-time tracking to keep you updated on the status of your order, giving you peace of mind and full transparency into the delivery process.

Why Choose MACRO NEO for Manufacturing & Quality Control?

- Comprehensive Manufacturing Capabilities: From supply chain management to production monitoring and quality control, we provide a holistic approach to manufacturing that ensures the highest product quality and efficiency.

- Strict Quality Standards: Our rigorous quality control systems ensure that every product meets the highest standards of performance, safety, and compliance.

- Efficiency and Scalability: We use the latest manufacturing technologies and lean principles to optimize production and adapt to changing demand, helping you meet tight deadlines and achieve cost savings.

- Global Reach: Our global logistics network ensures that your products are delivered on time, anywhere in the world, with minimal hassle.

Get in Touch with MACRO NEO

At MACRO NEO, we are committed to delivering products that exceed your expectations through our robust manufacturing and quality control processes. Whether you are looking for small-batch production or high-volume manufacturing, we ensure the highest standards of efficiency and quality at every stage. Contact us today to learn more about how our manufacturing and quality control capabilities can support your product's success.