ODM Services

ODM Design, Development, and Manufacturing: Full-Process Service from Concept to Mass Production

At MACRO NEO, we specialize in providing comprehensive ODM (Original Design Manufacturer) solutions, guiding our clients through every stage of the product development process. From concept design to mass production, we work as an extension of your team, ensuring the successful creation, prototyping, and manufacturing of high-quality products that meet your market needs.

Our full-process ODM service is designed to simplify the development cycle, reduce time to market, and guarantee high standards of quality. Whether you're launching a consumer electronics device, a smart home product, or a custom industrial solution, we manage every step with precision, ensuring your product is designed for success.

1. Concept Design: Turning Ideas into Vision

The product journey at MACRO NEO begins with a deep understanding of your business goals and vision. In the concept design phase, our team collaborates closely with you to transform ideas into a tangible design direction.

- Understanding Your Requirements: We start by discussing your target market, user needs, and functional specifications. These insights help us shape the core features, design aesthetics, and differentiators that set your product apart in the marketplace.

- Industrial Design & User Experience: Our industrial designers create conceptual drawings and 3D models of your product, ensuring it not only looks great but also provides an intuitive and enjoyable user experience. We prioritize ergonomics, usability, and the overall brand identity in our design.

- Feasibility Analysis: We conduct a feasibility study to assess the technical, financial, and manufacturing feasibility of your concept. This includes evaluating materials, technology choices, and supply chain constraints.

At this stage, we refine the design concept, ensuring it aligns with both your vision and market requirements.

2. Detailed Product Development: Refining Design and Prototyping

Once the product concept is finalized, MACRO NEO moves to the detailed product development stage, where we focus on turning the design into a functional, manufacturable product.

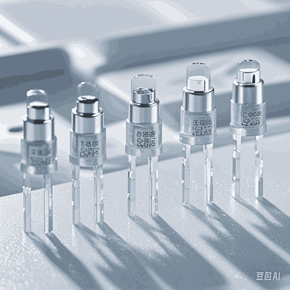

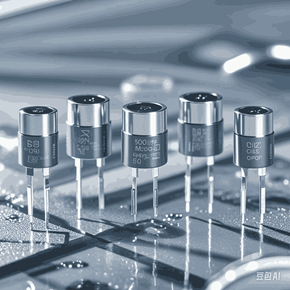

- Mechanical & Electrical Engineering: Our engineers focus on developing detailed specifications for the product's hardware, electrical circuits, and PCB layout, ensuring the product design is cost-effective, manufacturable, and scalable.

- Firmware & Software Development: If your product requires software, we design and develop custom firmware or embedded software, ensuring it integrates seamlessly with the hardware. We focus on creating software that is intuitive, responsive, and secure.

- Rapid Prototyping: We produce prototypes using 3D printing, CNC machining, and other advanced techniques to quickly bring your concept to life. This allows us to test the product’s functionality, aesthetic design, and user experience in real-world conditions.

- Testing and Validation: Once the prototype is ready, we conduct rigorous functional tests, stress tests, and compliance testing (e.g., CE, FCC) to ensure the product meets all relevant standards and is ready for mass production.

Feedback from these tests is used to refine and finalize the design before moving forward.

3. Pre-Production and Pilot Runs: Preparing for Large-Scale Manufacturing

Before scaling up to mass production, MACRO NEO conducts a pilot run to ensure all systems are ready for efficient, large-scale manufacturing.

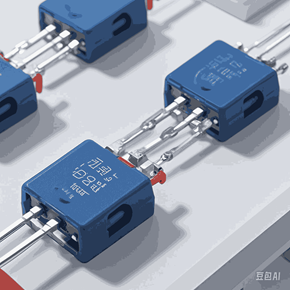

- Tooling and Molding: We create custom molds, injection tools, and set up assembly lines tailored to your product’s unique requirements. This ensures the manufacturing process is optimized for high-volume production, cost efficiency, and consistent quality.

- Pilot Production: A small batch of products is produced for evaluation. This helps to identify any potential issues with the assembly process, product functionality, and quality control before proceeding to full-scale manufacturing.

- Quality Control and Iteration: During the pilot phase, we focus on quality assurance to refine the product’s design, manufacturing processes, and any issues that may arise. We iterate on the design to ensure that it is fully ready for mass production.

This phase serves as a final verification before moving into large-scale production, ensuring that your product meets all quality and manufacturing standards.

4. Mass Production: Scaling for Market Demand

With the pilot run complete, MACRO NEO moves to mass production, where we manufacture your product at full scale for global distribution.

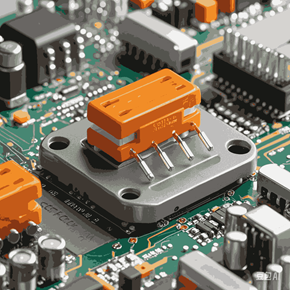

- Manufacturing Setup: Our experienced team prepares for large-scale production by setting up production lines, quality control stations, and fine-tuning the workflow to ensure maximum efficiency and minimal waste.

- Supply Chain Management: We manage the entire supply chain, sourcing raw materials and components from our trusted network of suppliers. Our logistics team ensures timely delivery of parts, avoiding any production delays.

- Production Quality Control: At MACRO NEO, we adhere to strict quality standards during mass production. We use automated testing systems and conduct final inspections to ensure that each unit is defect-free and performs as expected.

Throughout this phase, we monitor production closely to ensure that all units are produced to the highest standards of quality and meet your specifications.

5. Post-Production Support and Logistics: Delivering to Market

At MACRO NEO, we don’t just stop at manufacturing. We provide full post-production support, ensuring that your product is ready for the market and continues to perform throughout its lifecycle.

- Global Distribution: We manage the logistics and global shipping of your products, ensuring that they reach your customers, warehouses, or retailers on time and in perfect condition. Our team handles inventory management, customs clearance, and fulfillment to streamline the distribution process.

- Post-Launch Support: Our support continues after the product is launched, with services including firmware updates, maintenance, and customer support. We gather user feedback to help improve future versions of the product.

- Sustainability and Compliance: We ensure that all products meet the required industry certifications and environmental regulations. We also support sustainability efforts, such as the use of eco-friendly materials and practices in production.

Why Choose MACRO NEO’s Full-Process ODM Services?

- End-to-End Solutions: From initial concept to mass production, we manage every stage of the product lifecycle, ensuring seamless integration across all phases.

- Tailored to Your Needs: We customize our approach to your unique requirements, whether you're developing a consumer electronics device, smart home product, or industrial solution.

- Fast Time to Market: With our streamlined processes and global manufacturing capabilities, we help you get your product to market quickly without compromising on quality.

- Cost Efficiency: By managing the entire design and production process, we help you reduce costs and maximize profitability.

- Global Expertise: We leverage our experience in working with clients across various industries to provide solutions that are not only innovative but also reliable and scalable.

Get in Touch with MACRO NEO

At MACRO NEO, we are committed to bringing your ideas to life. From concept design to mass production, our team of experts is dedicated to providing high-quality, cost-effective solutions that meet your needs. Contact us today to learn more about how we can support your product development and manufacturing journey.